Woodception

I've always had a craze for arduinos and had one lying about that i'd been tinkering with. When I heard about the RepRap Project I was intrigued.

A home-made 3d printer out of simple parts! And this printer can be used to print better printer! I dont know any tech nerd that would be able to resist that kind of thinking!

The only thing is I really wanted a CNC machine so i could make some cool stuff out of wood. So i figured i'd make a CNC out of simple wood and simple tools I had at home. The only tools I had at my disposal were a drill and a really simple saw. We lived in a condo at the time and there really was no room to mess it up with sawdust or make noise to disturb the neighbours.

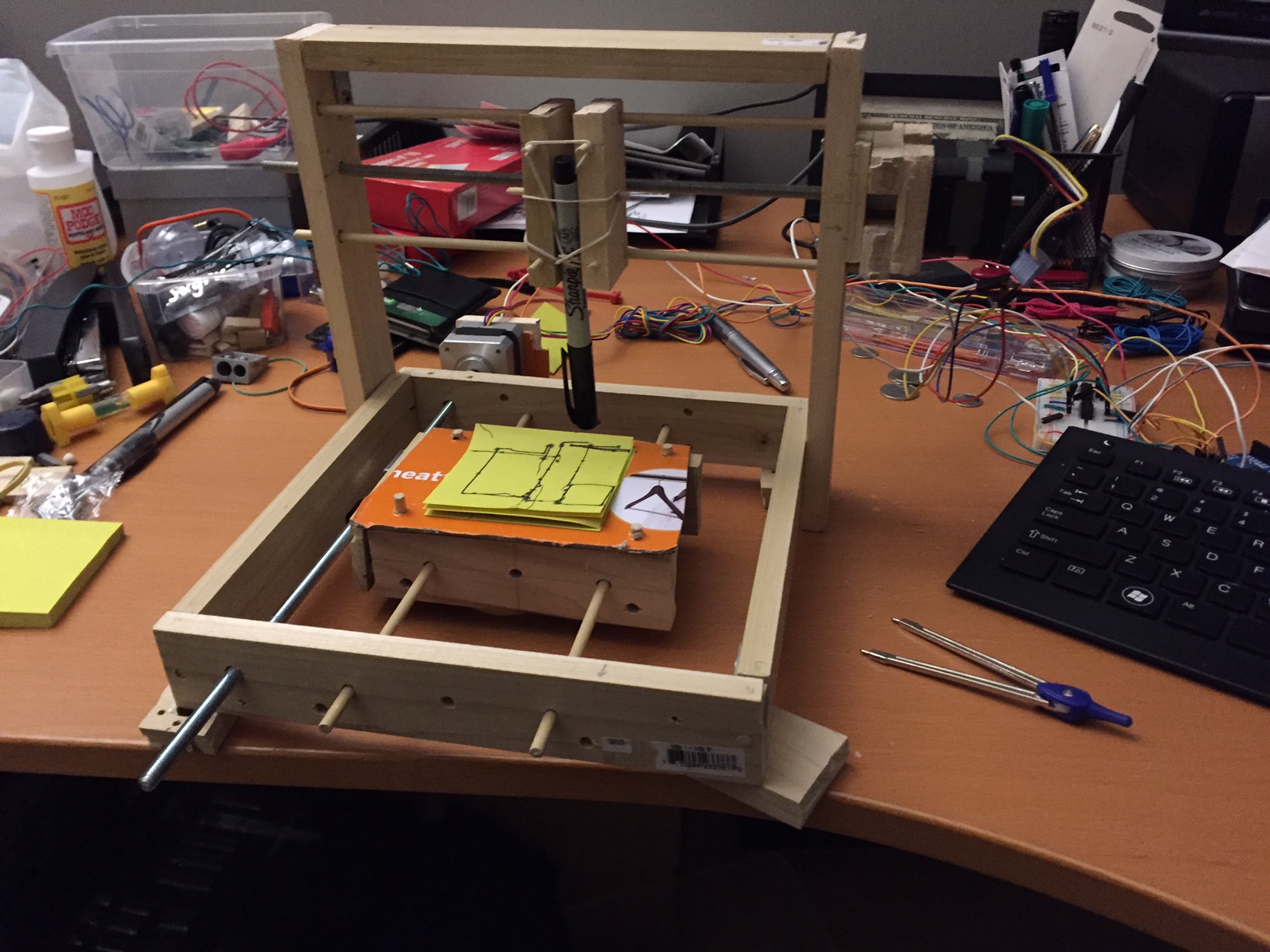

Version 1

Here's the first cut with just the X-Y motors and frame. The stepper motors drove threaded rods (coupled with simple nylon couplers and glue). The bed and X axis head had coupling nuts glued on and they were screwed onto the rods. I used a marker to simulate the head while testing the software on the arduino driving the motors.

Even the axles that the heads and bed rode on were simple wooden dowels. It actually all worked relatively well.

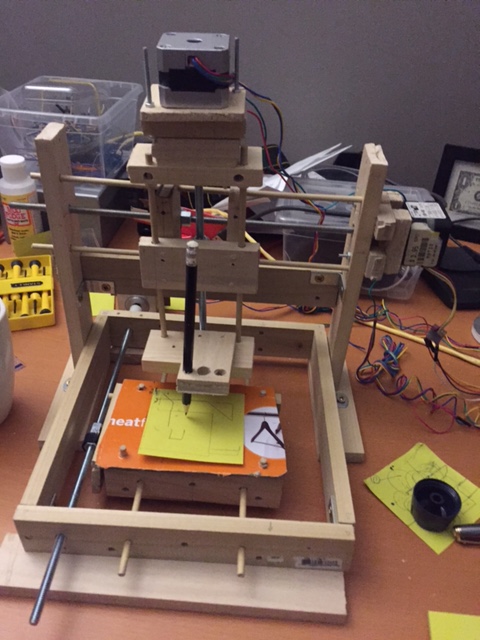

Version 2

Later I added the Z axis motor, and a better mount for the pencil for testing the code.

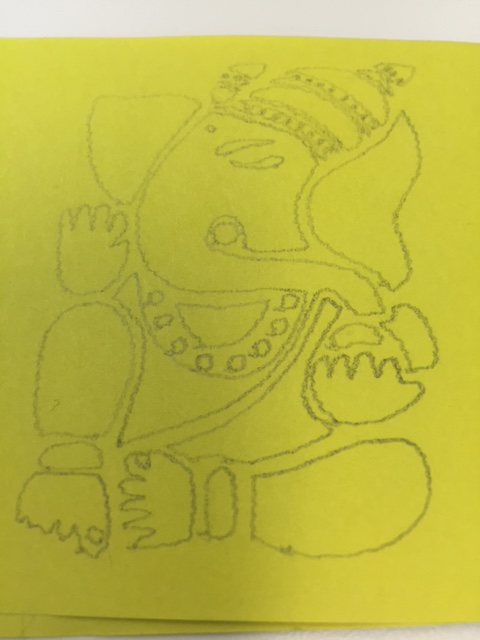

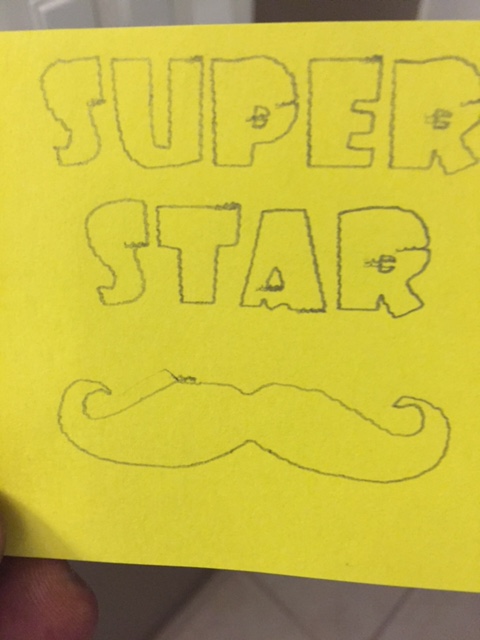

Plotter test

Of course I had to draw something cool to show people. The whole rig actually worked well despite all the shaking and sagging of axles. Below are a couple of sample drawings on post-it notes. The first picture was an homage to Ganesha - the remover of obstacles - for good luck.

Software

I had the arduino plugged directly to the motors using a darlington driver chip, and external voltage supply.

The code was all very rudimentary code on Arduino, and entirely custom written. The desktop app would read G-code commands from a file, and translate those into x/y movement to send to the arduino via COM port. The motors would then move to specified position. There was no acceleration control or speed control to reduce jerkiness.

I used Inkscape's G-code plugin to convert vector graphics into g-code

Indeed the whole frame was a bit wobbly - I mean the axles were made of wood!

Death of a project

So this is where my wife decided I'd done enough drilling and sawing inside our apartment. The project came to an abrupt end.

But thats ok - this is when I decided a 3d printer would be more appropriate for the apartment :)

Learnings

I learnt a lot from all of this.

- Wood is good because its flexibile. I made a bunch of mistakes drilling holes and aligning things - especially for the double rails that the base needed to slide on. Because wood is more forgivin i was able to somehow make it work.

- Wood is bad because its flexibile - the rails certainly were horrible to hold up heavier weight items - should have gone with metal.

- Precision requires good parts. This thing was quite shaky, and realistically it would not have been good enough to use as a CNC.